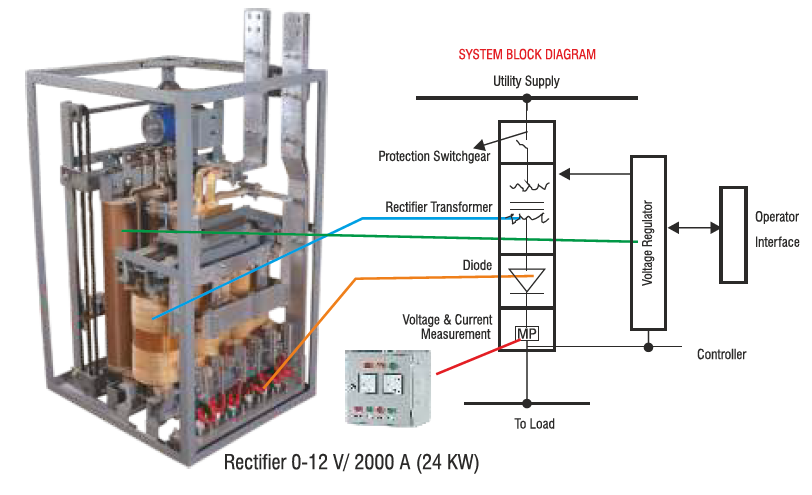

RECTIFIER (D.C. Power Supplies) - ROLLING CONTACT TECHNOLOGY

With Its easy convertibility from one voltage to another A.C. (Alternating Current) reigns supreme in the generation transmission and distribution Systems. Yet DC (Direct Current)/ DC power supplies for Electroplating Plants, Electro chemical plants, Copper, Aluminium & Zinc Refining all requires modest Voltage and high DC current. DC power is also required in other Industrial processes like Hydrogenation & Electrolysis. Such continuous Power Industries look for a ‘Reliable’ economical and trouble free form of DC Power supply Systems. ‘Reliable’ offers a complete range of Rectifier Equipments for all such application and provides Engineering, Design and Technical support in choosing the right solution / Equipment.

Applications

- Electroplating (Chrome Plating, Hard Chrome Plating, Zinc Plating, Nickel Plating, Copper Plating, Gold Plating, Silver Plating etc.)

- Cathode Electro Deposition (C.E.D. Coating)

- Anodizing Anodized Electro Coloring, Hard Anodizing.

- Heating Furnace, Magnetization, Ionization.

- Electroforming

- Hydrogenation, Electrolysis

- Copper, Aluminium & Zinc Refining

General Specifications

| AC Input | Voltage | 380/440 volts |

| Phase | 3 | |

| Frequency | 50 Hz | |

| Customization | High Voltage Input up to 11 KV | |

| DC Output | Voltage | 8,12,16, 24 volts, 50 volts, 100 volts, 150 Volts, 200 Volts & 500 Volts |

| Current | 0-20 KA | |

| Customization | Power Systems up to 20 KA and voltages up to 500 V DC are available. |

Efficiency: Reliable’s Power Supplies are highly efficient with typically efficiency between 85-95% depending upon the DC voltage of the Unit.

Power Factor: 90% Rated output.

Rating: All components are rated as a standard for 100% continuous full load service in an ambient Temperature of 50°C.

Temperature: ‘Reliable’ design its systems for a maximum rise of temperature of 35°C at the top of the oil with an ambient temperature of 50°C.

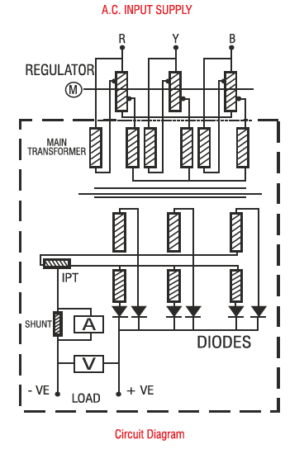

Ripple Factor: As we use Double Star Hexa Phase Circuit with Interphase Transformer. So the ripple content is always Less than 4.5%.

Standard Features

Design: – Our Sales/Design Engineers are available to work with you to meet all of your product requirements. All components are designed to provide 100% continuous full load operation.

Electronics :- Our precision Electronics are designed and manufactured to provide proven stable operation with ± 5.0% voltage/current regulation throughout the nominal range from 10%-100% of DC output.

Transformer

Winding Material :– Splice free, electrolytically pure copper 99.9%

Core Material: – Low Loss, High quality, Grain Oriented Silicon Steel provides good flux and low eddy current losses

Insulation Material : – ‘A’ Class Insulation is used for ONAN systems.

Process :- The coils are vacuum impregnated by Varnish and then baked to cure. Varnishing provides additional electromechanical Strength. All coils are wound for stress distribution under fault conditions to provide superior mechanical strength.

Cooling: – ‘Reliable’ supplies are designed for optimum low loss/efficient operation and employ specially designed natural oil cooling to remove the heat generated during operation.

Controls: – The following are examples of typically required Control configurations. ‘Reliable’ is committed to working with each Customer on an individual basis to ensure your Control requirements are satisfied.

- Standard Control (D. C. Metering, Push Buttons and Indicator lights in a panel on the machine)

- Manual – Remote

- Centralized control Panel for Number of Systems

- Constant Voltage Controller /constant current controller

- Zero Run Down System

- Ampere Hour Meter/Ampere Minute Meter

Semiconductors: ‘Reliable’ selects its semiconductors with an appropriate 200% safety factor to provide the ultimate in reliability. This design criterion limits the junction temperature of semiconductor to typically less than 800 C , thus enhancing the life of the equipment.

MS Shell : The enclosure i.e. mild steel steels are fabricated with 8/10/12 SWG HR sheets. The requisite supports along with seam welded cooling fins are provided to dissipate the heat produced. The housing is checked for leakage with pressure testing. The job is then paint finished inside and outside by degreasing and acid resistant Epoxy Paint. Standard Paint will be BS Grey. Change of shade on request.

Ripple: Standard 6 pulse DC Rectifier will contain less than 5% RMS AC Ripple when operated at Rated Voltage and Current.

Training: Reliable’s service Engineer may instruct our customer’s operator and Maintenance personnel during the commissioning /start of the unit or during final test at our works. This can be operational training and / or full Maintenance repair training.

Spare Parts: ‘Reliable’ maintains a considerable spare parts inventory and has the appropriate factory approved spare parts on hand and ready for your use to assure maximum uptime of your process. Reliable’s power supplies are designed for decades of trouble free performance when the installation and maintenance guidelines contained in the service manual are followed.

D.C. BUS BAR: ‘Reliable’ uses Electrolytically pure Copper/ Aluminium bus bar exclusively in our rectifier systems. Bus Block with bolted joints and flexible connections are designed to minimize bus losses and to match the client’s application requirement. The laminated bus structure designed maintain a low bus impedance and low voltage over shoot.

QUALITY CONTROL

Each piece of equipment we build is rigorously tested and put through a systematic quality control examination prior to dispatch. Our test facility utilize state of art equipment to verify that the Power Supply you receive is exactly what you ordered. Our staff of highly competent test technicians performs a full range of operational and functional testing and maintains complete documentation of all test procedures and results. Prior to dispatch/ shipment a final quality control inspection is performed.